| Test project | Standard of experiment | Equipment photo | |

| Operating temperature 85℃ (plug-in) "* 1" | Operating temperature 125℃ (SMD products) | ||

| High temperature storage | Crystal is placed at 85℃±2℃ for 1000 hours "*2" | Crystal at 125℃±2℃ for 1000 hours "*2" |  |

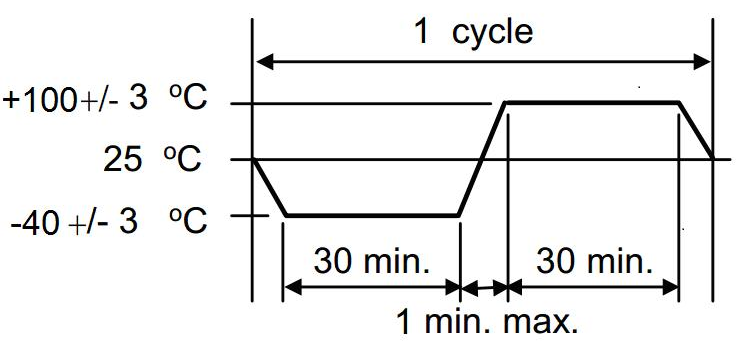

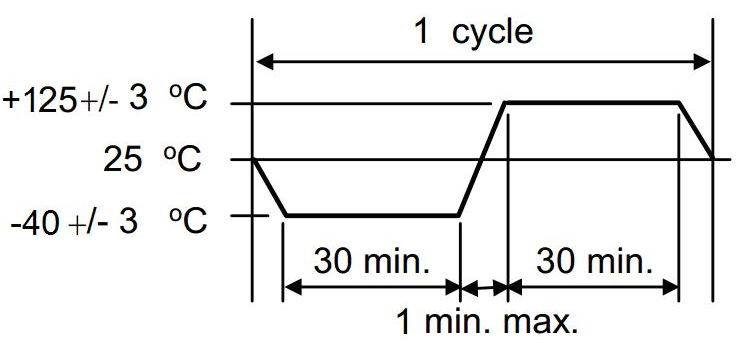

| Cycle of temperature | The crystal does 1000 cycles at the table temperature below | The crystal does 1000 cycles at the table temperature below |  |

| Steady moisture heat | The crystal is placed at 85 ° C ±2 ° C and 85% humidity for 1000 hours "*2" | The crystal is placed at 85 ° C ±2 ° C and 85% humidity for 1000 hours "*2" |  |

| Life of service | Crystal at 85 ° C ±2 ° C for 1000 hours "*2" (rated VDD applied) | Crystal at 125 ° C ±2 ° C for 1000 hours "*2" (rated VDD applied) |  |

| Appearance | Check device structure, marking and process quality.No electrical testing is required | Check device structure, marking and process quality.No electrical testing is required |  |

| Size | User and supplier specifications.No electrical testing is required | User and supplier specifications.No electrical testing is required |  |

| Strength of terminal (Plug-in class) | Tensile force: A 227g tensile force applied along the terminal axis for 10±5 seconds. Bending: The load should be limited to 2.5±0.5mm away from the Crystal Element body to start bending, the added mass load is 227g, bending times is 3. |  | |

| Impact | Impact mode Half sine wave 100G duration 6ms direction X, Y, Z axis, 6 sides, a total of 18 impacts |  | |

| Vibration | Vibration frequency 10 ~ 2000Hz Spoke 1.5mm Scanning time 20 min Directions X, Y and Z(12 cycles in each of the three directions) |  | |

| Resistance to welding heat | Reflow soldering: Peak temperature: 260±5℃, time: 10 seconds ±1 second. |  | |

| Ability to weld | Welding temperature 245℃±5 ℃ immersion time 5 seconds ±0.5 seconds, flux rosin resin methanol solvent (1:4) |  | |

| Characteristic of electrical properties | Perform parameter tests according to batch and sample number requirements, and summarize and list the minimum, maximum, mean and standard deviation of the device at room temperature and the lowest and highest operating temperatures. |  | |

| Panel bending (SMD) | Apply pressure to the center of the product until it bends to a minimum of 2mm and holds for 60±5 seconds. |  | |

| Terminal strength (SMD) | A force of 1.8Kg was applied laterally for 60±1 second. |  | |

No. 2569, North Tianmenshan Road, Tongling Economic and Technological Development Zone, Anhui Province, China | |

0562-5886356 | |